Diaphragm carburetor troubleshooting is one of the fastest ways to bring a “dead” string trimmer, chainsaw, or leaf blower back to life without replacing the whole small engine. With a few basic checks, some cleaning, and a low‑cost diaphragm kit, many “carb not working” issues can be fixed in under an hour—even if you’re a DIY beginner.

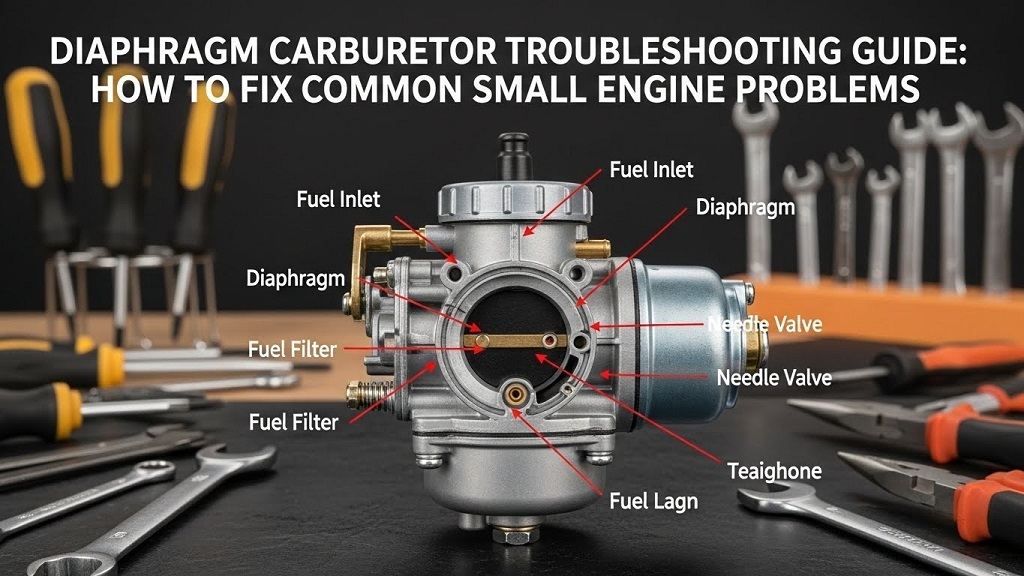

What a diaphragm carburetor does

A diaphragm carburetor meters and pumps fuel from the tank into the engine using a thin rubber diaphragm instead of a float bowl. This design lets small engines run in any position, which is why it’s used on string trimmers, chainsaws, blowers, and many other handheld tools.

Inside the carburetor, the metering diaphragm and fuel pump diaphragm react to engine vacuum pulses to control how much fuel enters the carb body. When these rubber parts harden, tear, or stick, you get classic small engine carburetor problems such as no‑start, bogging, or stalling under load.

Common signs of diaphragm carburetor problems

Many “engine is dead” complaints are really diaphragm carburetor troubleshooting cases waiting to happen. Typical symptoms include:

-

Hard starting or only starting on choke.

-

Engine stalls when you hit the throttle or won’t rev up under load.

-

Rough idle, hunting, or dying at low speed.

-

Fuel leaking from the carburetor or primer bulb, or strong fuel smell.

-

String trimmer runs only in odd positions (for example, only when tilted or upside down).

If your small engine has spark, compression, and fresh fuel, yet still shows these symptoms, the diaphragm carburetor is a prime suspect.

Quick checks before blaming the carb

Before diving into diaphragm carburetor troubleshooting, rule out other basics so you don’t chase the wrong problem.

-

Verify good spark and correct plug gap with a known‑good spark plug.

-

Confirm fresh, properly mixed fuel (for 2‑stroke) and a clean in‑tank fuel filter.

-

Inspect the air filter and exhaust screen; severe clogging can mimic carburetor problems.

-

Make sure carburetor and intake bolts are snug to avoid vacuum leaks.

Once these are confirmed, you can focus on small engine carburetor problems confidently without second‑guessing ignition or compression.

Why diaphragm carburetors stop working

Understanding what actually fails helps you fix a diaphragm carburetor not working instead of just replacing parts blindly.

-

Hardened or stiff diaphragms: Ethanol fuel and age dry out the rubber so it can no longer flex, causing lean running, bogging, or no‑start.

-

Torn or punctured diaphragms: Holes let fuel bypass or leak, throwing the metering action off and often causing rich running, fuel leaks, or flooding.

-

Blocked jets and internal passages: Varnish, dirt, or corrosion clog the tiny holes that meter fuel, starving the engine even if the pump is working.

-

Incorrect metering lever height or weak spring: If someone has “tinkered” before, the lever can sit too high or low, changing fuel delivery and causing hesitation or flooding.

Most string trimmer carburetor issues trace back to one or more of these faults, and they are usually solved by cleaning plus a diaphragm/gasket kit.

Step‑by‑step diaphragm carburetor troubleshooting

Follow this basic workflow for small engine carburetor problems on trimmers, chainsaws, and similar tools.

Identify the carb and get a kit

Look up your model number and order the correct diaphragm/gasket or rebuild kit, which typically includes a metering diaphragm, pump diaphragm, and gaskets. Using the wrong kit can cause small passages to misalign and create new carburetor issues.

Drain fuel and remove the carburetor

Shut off or drain the fuel tank and disconnect the spark plug for safety. Carefully remove throttle linkages, fuel lines, and mounting screws so the carburetor comes off without bending linkages.

Open both sides of the carb

One cover usually hides the fuel pump diaphragm; the other hides the metering diaphragm and needle. Note the diaphragm and gasket order or take a photo so you can reinstall them correctly later.

Inspect diaphragms and gaskets

Check for stiffness, warping, cracks, or pinholes by gently flexing each diaphragm. Any sign of damage or hardness means replacement rather than reuse.

Clean internal passages

Spray carburetor cleaner through jets, passages, and ports, then blow them out with compressed air to remove varnish and debris. Avoid wire drills in tiny jets; scratching them can permanently alter fuel flow.

Check the metering needle and lever

With the metering diaphragm removed, inspect the needle tip and lever for wear, dirt, or sticking. Reinstall with the spring in place and the lever at the correct height for your carb design (often roughly level with the carb body, but refer to model‑specific data).

Install new diaphragms and gaskets in correct order

Some carbs require “gasket first, then diaphragm,” while others reverse the order, especially under the fuel pump cover. Incorrect stacking is a common reason a diaphragm carburetor not working will stay that way even after a rebuild.

Reassemble, reinstall, and test

Refit the carb, reconnect fuel lines and linkages, and ensure there are no kinks. Prime, start the engine, and let it warm up before touching the adjustment screws.

Adjusting a rebuilt diaphragm carburetor

Once mechanical issues are sorted, many remaining string trimmer carburetor issues are tuning‑related.

-

Most small diaphragm carbs have a low‑speed (L), high‑speed (H), and idle speed screw. Start at manufacturer’s baseline turns‑out from gently seated and fine‑tune from there.

-

Adjust the L screw for smooth idle and clean takeoff without bogging, then set the idle speed screw so the head does not spin at idle.

-

Tune the H screw at full throttle under light load, aiming for strong power without a lean, screaming tone; err slightly rich for engine safety.

If adjustments have little to no effect, there may still be internal restrictions, air leaks, or incorrect diaphragm/gasket orientation inside the carburetor.

Frequent string trimmer carburetor issues (and fixes)

Here are some typical small engine carburetor problems for string trimmers and how diaphragm carburetor troubleshooting solves them.

-

Trimmer only runs on choke: Usually a lean condition from clogged jets, stiff diaphragms, or air leaks; fix by cleaning the carb, replacing diaphragms, and checking intake gaskets.

-

Stalls when tilted or at full throttle: Often a worn or mispositioned metering diaphragm that cannot supply enough fuel when engine demand changes.

-

Fuel leaking from carb or primer bulb: Common with torn pump diaphragms, incorrect gasket stacking, or a stuck metering needle; a repair kit typically resolves it.

-

Won’t start after sitting all winter: Old fuel varnish plus dried diaphragms; cleaning plus a new diaphragm kit is usually cheaper and more reliable than a generic replacement carb.

Addressing these issues systematically can restore performance and extend the life of your trimmer, chainsaw, or blower.

Table: Symptoms and likely diaphragm carb causes

| Symptom | Likely diaphragm carb cause |

|---|---|

| Hard start, only runs on choke | Stiff diaphragms, clogged jets, air leak at carb/intake |

| Stalls on throttle, bogs under load | Weak or mis‑set metering system, lean mixture from blockage |

| Rough idle, hunting, dies at low speed | Idle circuit restriction, low‑speed mixture misadjusted |

| Fuel dripping from carb or primer | Torn diaphragm, leaking needle, incorrect gasket order |

| Runs only when tilted or upside down | Fuel pick‑up or metering diaphragm not tracking demand |

| No‑start after long storage | Varnished passages and dried diaphragms from old fuel |

Preventing future diaphragm carb problems

Once your diaphragm carburetor troubleshooting has paid off, a few habits will keep it working longer.

-

Use fresh, quality fuel and avoid storing ethanol blends in small engines for long periods.

-

At season’s end, either drain the tank and carburetor or use a fuel stabilizer according to the label.

-

Run the engine periodically to keep diaphragms flexible and fuel passages from gumming.

-

Replace diaphragms proactively every few years on heavily used commercial equipment.

These simple steps reduce string trimmer carburetor issues and save money on premature carb replacements.

FAQs about diaphragm carburetor troubleshooting

1. How do you know if a diaphragm carburetor is bad?

Common signs include hard starting, the engine only running on choke, stalling under load, rough idle, or visible fuel leaks from the carburetor or primer bulb. If ignition and compression are good and fresh fuel is present, these symptoms strongly point to diaphragm or internal carb problems.

2. Can you clean a diaphragm carburetor instead of rebuilding it?

Light varnish or minor debris can sometimes be cleared with carb cleaner and compressed air, improving performance. However, if the diaphragms are stiff, warped, or damaged, cleaning alone will not fix a diaphragm carburetor not working and a rebuild kit is recommended.

3. How often should diaphragm carburetors be rebuilt?

There is no exact schedule, but many small engine technicians replace diaphragms every few years on equipment that sees regular use, especially with ethanol fuel. Any time you have repeated small engine carburetor problems after long storage, a diaphragm and gasket kit is a smart starting point.

4. Why does my string trimmer only run on choke?

Running only on choke usually means the engine is not getting enough fuel or is drawing extra air, so the choke compensates by enriching the mixture. Common causes are clogged jets, air leaks, or hardened diaphragms inside the string trimmer carburetor.

5. Is it better to rebuild or replace a small engine carburetor?

For many diaphragm carburetors, a quality rebuild kit is cheaper and preserves the original, properly matched carb body. Replacement makes sense only when the carburetor casting is damaged, corroded, or the correct parts are no longer available.

Call to action

If your trimmer, chainsaw, or blower is hard to start or bogs under load, use this diaphragm carburetor troubleshooting guide as your next step instead of buying a new tool. Bookmark this article, gather a rebuild kit for your specific model, and walk through the checklist on your next small engine project—then share your results or questions in the comments to help other DIYers solve their small engine carburetor problems too

Related Topics: Essential Gear: How Faxco 10ft Rope Excels in Triple-Strand Design

Related Topics: Quick Pasta Nights: Testing Affordable Extruders for Busy Cooks